"AestheticsInMotion" (aestheticsinmotion)

"AestheticsInMotion" (aestheticsinmotion)

01/24/2019 at 21:57 ē Filed to: None

8

8

29

29

"AestheticsInMotion" (aestheticsinmotion)

"AestheticsInMotion" (aestheticsinmotion)

01/24/2019 at 21:57 ē Filed to: None |  8 8

|  29 29 |

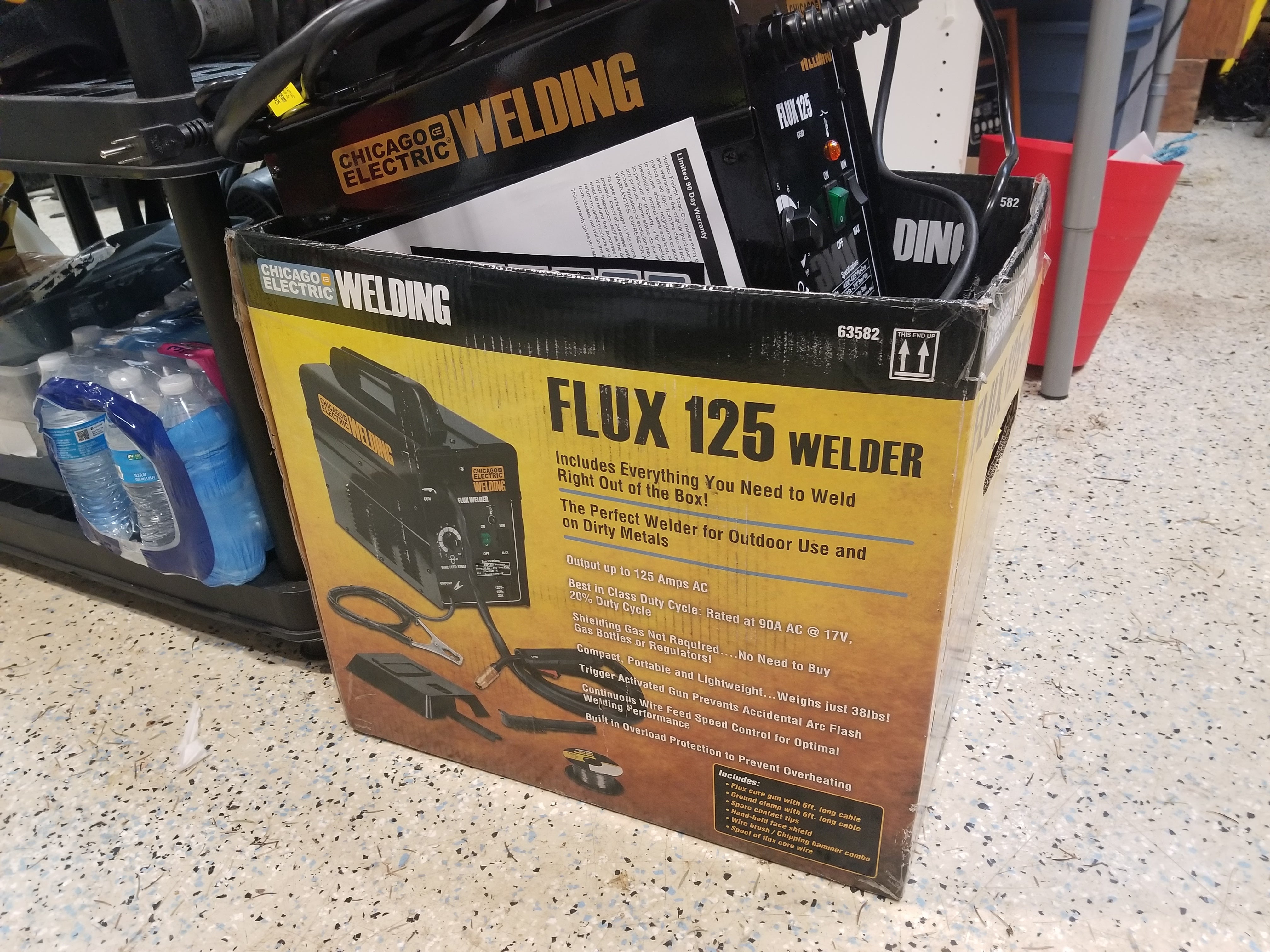

*Miatafications intensify*

Now where do I find scrap metal to practice on....

Also, any tips? Anything to keep in mind? I set the welder up today and hope to find time tomorrow to start practicing.

deekster_caddy

> AestheticsInMotion

deekster_caddy

> AestheticsInMotion

01/24/2019 at 22:09 |

|

I bought my own welder last year and have been doing a lot of work with it. Be patient. Welding sheetmetal is the trickiest thing - itís really easy to blow holes in your work because the metal is thin. Practice on scrap sheetmetal before you do it on the real thing. I ended up building my own exhaust system - that was a little easier because the metal gauge is thicker. Totally worth it. Iíve only had a few posts, if you can go back through my recent post history youíll see the exhaust I did, and rusted floor pans I rebuilt at the same time.

superdave847

> AestheticsInMotion

superdave847

> AestheticsInMotion

01/24/2019 at 22:16 |

|

Harbor Freight?

AestheticsInMotion

> superdave847

AestheticsInMotion

> superdave847

01/24/2019 at 22:28 |

|

Indeed. It SAYS it can weld 3/16 steel. Wonder if that's accurate†

AestheticsInMotion

> deekster_caddy

AestheticsInMotion

> deekster_caddy

01/24/2019 at 22:29 |

|

I remember those! Exhaust work is on the list. 99% sure there's a hole in either my header or downpipe†

Brian, The Life of

> AestheticsInMotion

Brian, The Life of

> AestheticsInMotion

01/24/2019 at 22:33 |

|

Ooh yay! Iíve been seriously pondering this purchase myself! Did you do much research before landing on the HF model? Iíve been considering getting one of those or biting the bullet and getting a Lincoln 180 from Home Depot or somewhere.

Wacko

> AestheticsInMotion

Wacko

> AestheticsInMotion

01/24/2019 at 22:44 |

|

auto dimming helmet, clamps, 2 magnetic welding squares(donít let the name fool you they are actually triangles) and welding gloves.

And this is flux core so you want to drag your weld.

I use 2 grinders, one with grinding disk and the other a sanding disk. Before and after the welds ( flux core welds leave boogers)

Practice, and get ready for some trips to the breaker box.

NKato

> AestheticsInMotion

NKato

> AestheticsInMotion

01/24/2019 at 22:46 |

|

awesome. Iíd be doing the same if I had a garage. I want to fabricate a custom center console for the Queen.

Also, ask Everett Metal Supermarket if they have any leftover scrap you can practice with.†

MM54

> AestheticsInMotion

MM54

> AestheticsInMotion

01/24/2019 at 22:49 |

|

A good auto-darkening mask is well worth the cost. Wear long sleeves and pants (and sparks will find their way down your leg if the knees have holes; this is droplets of

molten steel, not grinding

sparks so they hurt

). Be considerate if there are other people around; make sure they know when youíre about to start welding so you donít blind them.

I am far from being what Iíd consider a good welder, but have some experience. Youtube videos will help get you started with the basics. Iíd suggest getting some plate and just laying beads on it for a while to get a feel for it, both pushing and pulling. Afterwards, cut up some stock and start sticking it together in different ways.

Clean metal before welding it, wire brush/grinder/whatever to get it shining, then de-grease. I like acetone; DO NOT use brake cleaner, the chlorine compounds that make it do its thing (in any residual cleaner on the part) have some sort of reaction with the heat and UV from welding that turns it into basically nerve gas that will kill you (if youíre lucky).

Being flux-core youíll have more spatter and clean-up than a mig setup, but should be able to do structural stuff pretty well for sure (and sheetmetal if youíre careful and take the time for extra clean up afterwards).

Have fun!

VincentMalamute-Kim

> Brian, The Life of

VincentMalamute-Kim

> Brian, The Life of

01/24/2019 at 22:49 |

|

Get the Lincoln 180.

MM54

> Brian, The Life of

MM54

> Brian, The Life of

01/24/2019 at 22:51 |

|

The pictured machine is flux core only; the Lincolns that lowes/home depot carry I believe are mig machines, which let you do Ďnormalí mig under gas or use flux core (

gasless)

.

MM54

> Wacko

MM54

> Wacko

01/24/2019 at 22:52 |

|

The ď2 grindersĒ thing is huge, saves so much time.

Wacko

> MM54

Wacko

> MM54

01/24/2019 at 22:56 |

|

I need a 3rd one for †cutting disks

AestheticsInMotion

> Brian, The Life of

AestheticsInMotion

> Brian, The Life of

01/24/2019 at 23:03 |

|

Zero research. It was on sale for $8 0 with an auto-dimming visor, gloves, welding squares, hammer, and a few other things included so... Figured it would be a good platform to lear n on

MM54

> Wacko

MM54

> Wacko

01/24/2019 at 23:04 |

|

These days I work the die grinder into the mix. Itís slower for grinding stuff down but it works well for prep.

ITA97, now with more Jag @ opposite-lock.com

> AestheticsInMotion

ITA97, now with more Jag @ opposite-lock.com

> AestheticsInMotion

01/25/2019 at 00:38 |

|

Practice, practice, practice... Once youíre getting pretty welds with penetration on scrap, then start whacking them with a sledge hammer after cooling. When welds start holding, youíll know you can try welding on something that matters.

A lot of shops have scrap steel piles or bins outside in the parking lot for the taking. At the hydraulic shop, there was old dude in a 70's Toyota truck that went around to every shop in that area of Albuquerque once every couple of days and took whatever was out. Copper, brass and aluminium we kept inside and recycled ourselves a couple of times a year, followed by lunch and beers for everyone at Twin Peaks on a Friday afternoon, but scrap steel and cast iron wasnít worth our time to load up and sell to a recycler for a penny and half a pound.

If you donít have one, get a proper heavy duty extension cord and keep the run as short as possible. Welders arenít happy with voltage drops. https://www.amazon.com/AmazonBasics-SJTW-Heavy-Duty-Lighted-Extension/dp/B01IN11PFQ/ref=sr_1_2_sspa?ie=UTF8&qid=1548393921&sr=8-2-spons&keywords=welding%2Bextension%2Bcord&th=1

†

StudyStudyStudy

> AestheticsInMotion

StudyStudyStudy

> AestheticsInMotion

01/25/2019 at 02:43 |

|

Hmm flux is pretty irritating. Basically got to go over the area 3 times. The bummer is that the control is pretty limited so unless you are doing bigger structural welding you have a risk of blowing through the thinner stuff like sheet metal. Let me know if you need a lesson!†

Chinny Raccoon

> Wacko

Chinny Raccoon

> Wacko

01/25/2019 at 04:49 |

|

Never enough grinders.

farscythe - makin da cawfee!

> AestheticsInMotion

farscythe - makin da cawfee!

> AestheticsInMotion

01/25/2019 at 08:39 |

|

got a sawzall?

head over to the junkjard pick up some scrap exhausts

cut em up and weld em back together

Pickup_man

> AestheticsInMotion

Pickup_man

> AestheticsInMotion

01/25/2019 at 09:18 |

|

A few tips that I got that worked wonders with my flux core welding;

Thin wire, .030 unless youíre welding something very thick, and quality wire, Iím not sure about all of the brands, but Iím using Forney and it works well.

I was told by a professional welder that with flux core you push the weld, which has helped for me, but I see someone has said to drag it, so donít hold me accountable for that one, itís just something that worked for me.

Keep the gun a decent distance from the part, 3/4 Ē -1 " or so. The shielding gasses come from the wire itself so the cone on the gun does nothing for you in terms of protecting the weld. Play around with what distances you like, but keeping it back a little bit has helped me see and control my weld better.

The cleaner the metal the better. At a minimum hit it with a flapper disc or sand paper and wipe it clean. Apparently donít use brake cleaner, (oops, at least I let it fully dry so hopefully that helps? ), use acetone like others have recommended .

As always, practice practice practice.†

AestheticsInMotion

> Wacko

AestheticsInMotion

> Wacko

01/25/2019 at 17:32 |

|

So do you grind, then sand, before and after the welds?

AestheticsInMotion

> MM54

AestheticsInMotion

> MM54

01/25/2019 at 17:33 |

|

Brake cleaner scares me

AestheticsInMotion

> farscythe - makin da cawfee!

AestheticsInMotion

> farscythe - makin da cawfee!

01/25/2019 at 17:34 |

|

Not an awful idea. I'll be at a junkyard anyways....†

AestheticsInMotion

> StudyStudyStudy

AestheticsInMotion

> StudyStudyStudy

01/25/2019 at 17:40 |

|

Iím hoping to do more structural welding óshelving, thick brackets, stands, work vehicle additions óso maybe this will be a good fit? The plan is to wait until Iíve learned a bit more before attempting anything on my personal vehicles.

I would definitely like a lesson at some point!†

MM54

> AestheticsInMotion

MM54

> AestheticsInMotion

01/25/2019 at 17:54 |

|

I use it for most anything other than welding prep and painted things I want to keep nicely painted.

StudyStudyStudy

> AestheticsInMotion

StudyStudyStudy

> AestheticsInMotion

01/25/2019 at 20:01 |

|

To play around with it may be nice, and if you end up going with a MIG later you will appreciate not having to go over your welds several times. It is going to teach you some weird habits, but in truth even MIG will teach you some not so good habits. Given your situation it may be more ideal though as the only real benefit to flux is that it can be used outdoor in the wind, and without a dedicated shop that may be a boon.

farscythe - makin da cawfee!

> AestheticsInMotion

farscythe - makin da cawfee!

> AestheticsInMotion

01/25/2019 at 20:15 |

|

for what its worth... most beer cans are aluminum

just saying :p

Wacko

> AestheticsInMotion

Wacko

> AestheticsInMotion

01/25/2019 at 23:59 |

|

All depends on what you are working with. Sanding wheels are great for painted or rusted metal. †And the grinder is great to shape your pieces before you weld. †You need to clean your weld with a metal brush fairly often too.

Then I like to clean up the rough with the grinder then I polish it up with the sanding disk before paint.

Brian, The Life of

> MM54

Brian, The Life of

> MM54

01/26/2019 at 13:33 |

|

For sure, I meant get the HF version or spend more for a better unit. I wonít be using it often ... until I get it and realize how much I needed it lol

deekster_caddy

> AestheticsInMotion

deekster_caddy

> AestheticsInMotion

01/27/2019 at 20:00 |

|

I said exhaust work was easier, but in reality only the welding itself was easier. Itís a challenge to create a good seal all the way around the pipe...† that took some practice pieces to get the hang of, and I still had to seal up a couple holes on the vehicle, and in the worst places to reach of course...